Viscometers / In-flow Viscometer

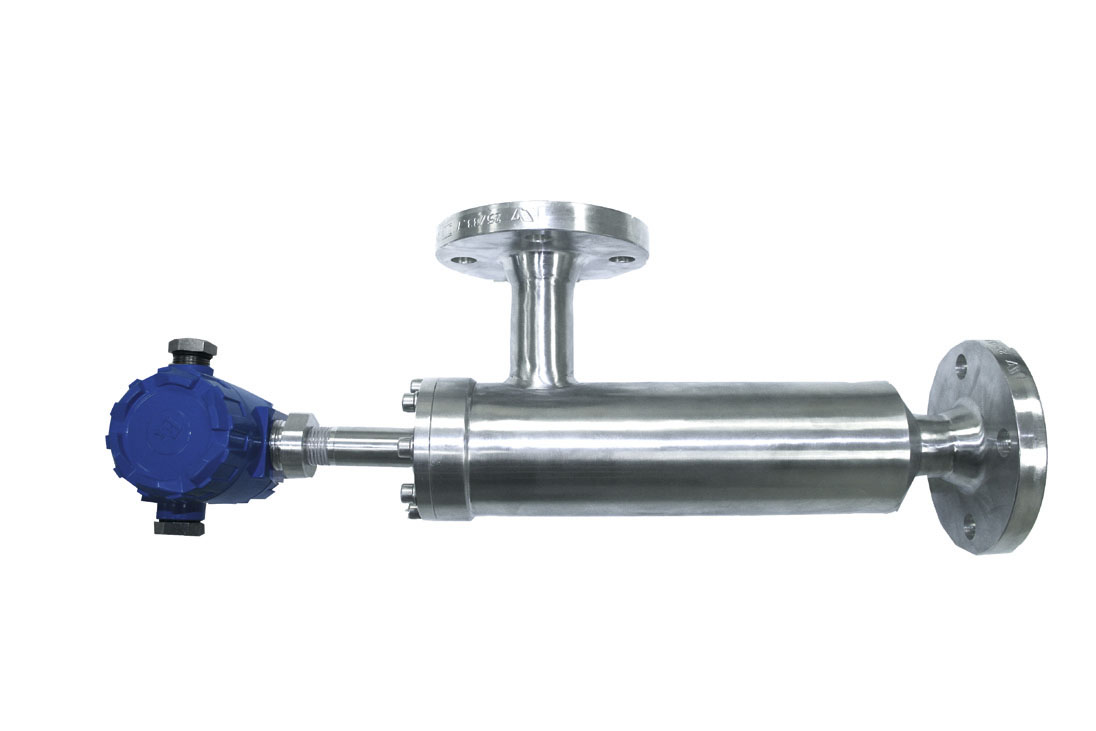

In-flow Viscometer DC-51

- Continuous measurements

- Easy cleaning

- High accuracy

- Simple installation

- Suitable for very viscous liquids

- Wide range ofapplications

- Compact design

- Automatic viscosity/temperature compensation

- Rigorous factory testing

- Safe operation, low maintenance

Overview

LEMIS process DC-51 series processes liquid viscometers are ideal for real-time, in situ monitoring and it controls applications within the oil, petrochemical, chemical, food and many other industries.

LEMIS process uses the proven vibrating element technique which is widely accepted as it enhances the most as one of the most accurate method of continuous online dynamic viscosity measuring. LEMIS process engineers made new developments by introducing the unique proprietary design of the resonance tube sensor allowing accurate measurements to be taken in liquid. An integral high accuracy Pt-1000 probe continuously monitors liquid temperature allowing temperature compensation and future calculation of kinematic viscosity. The technology proves high accuracy of measurement and long term calibration stability even in severe operation conditions. It is insensitive to plant vibration, high variation of temperatures or turbulence. A choice of wetted parts materials: from stainless steel for general industrial use, Ni-Span-C for most demanding applications, and Hastelloy for applications where ultimate corrosion resistance is required.

LEMIS process uses the proven vibrating element technique which is widely accepted as it enhances the most as one of the most accurate method of continuous online dynamic viscosity measuring. LEMIS process engineers made new developments by introducing the unique proprietary design of the resonance tube sensor allowing accurate measurements to be taken in liquid. An integral high accuracy Pt-1000 probe continuously monitors liquid temperature allowing temperature compensation and future calculation of kinematic viscosity. The technology proves high accuracy of measurement and long term calibration stability even in severe operation conditions. It is insensitive to plant vibration, high variation of temperatures or turbulence. A choice of wetted parts materials: from stainless steel for general industrial use, Ni-Span-C for most demanding applications, and Hastelloy for applications where ultimate corrosion resistance is required.

Documentation

Specifications

|

Viscosity Range |

0.2 to 2000 mPa·s (0.2 to 2000 cP) |

|

Viscosity Accuracy |

±1% of span |

|

Viscosity Repeatability |

±0.5% of span |

|

Viscosity Resolution |

0.1 mPa*s (0.1 cP) |

|

Pressure Range |

Up to 100 Bar |

|

Temperature Range |

-200°C to +200°C (-328°F to +392°F) |

|

Temperature Accuracy |

±0.1°C (±0.2°F) |

|

Ambient temperature |

-40°C to +85°C (-40°F to +185°F) |

|

Viscosity compensation |

Automatic |

|

Temperature compensation |

Automatic |

Applications

- Petroleum industry

- Ethanol production

- Food & Beverages

- Chemical industry

- Cosmetic industries

- Process monitoring control

- Ethanol production

- Food & Beverages

- Chemical industry

- Cosmetic industries

- Process monitoring control